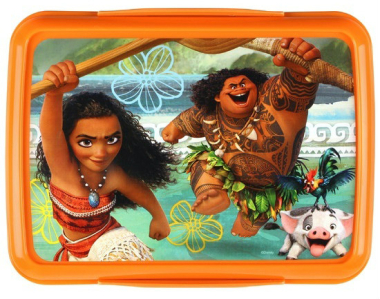

High-quality images can be added to multiple surfaces of a package or container through the inmould labelling process - these beautiful vibrant images will increase your product's shelf appeal to consumers and make them stand out on the shelves or in the chillers.

IMLs as we call them, are a favourite of brand managers, as they allow them to better position their brands amongst the visual "noise" of the crowded retail environment.

Admark is somewhat unique in that we use UV flexographic technology for our inmould labels. UV flexographic colours are stronger and brighter than the traditional off-set printing process, due to there being more pigments in flexographic inks. We can offer accurate colour-matching and excellent pictorial reproduction.

So what is an inmould label?

An inmould label is fused into the walls of a container during the moulding process; the result being an encapsulated label that is a durable alternative to traditional adhesive labels and prevents moisture or contamination from getting in behind the label.

What are the benefits of inmold labels?

- vibrant, photo-realistic colours and images

- increased shelf appeal

- flexibility - you can apply images and branding to almost any surface

- durable - the label is embedded in the plastic so almost impossible to scratch or scuff and is very resistant to fading or damage

- smooth, edgeless surface – excellent for food and FMCG products

- reduced manufacturing time - the whole moulding and decorating process is achieved in one go, rather than having to be moulded and then decorated

- the label and container are produced from the same material, so the entire product is recyclable and environmentally friendly

So if you think an inmould label could be right for you, give us one of our consultants a call.